Dr Neill Campbell collaborates on research to improve malaria diagnosis

News

Dr Neill Campbell is collaborating with Dr Richard Bowman (Department of Physics) as well as researchers from the University of Cambridge, Ifakara Health Institute and project partners TechforTrade, the Wellcome Sanger Institute and WaterScope on two EPSRC funded malaria research projects.

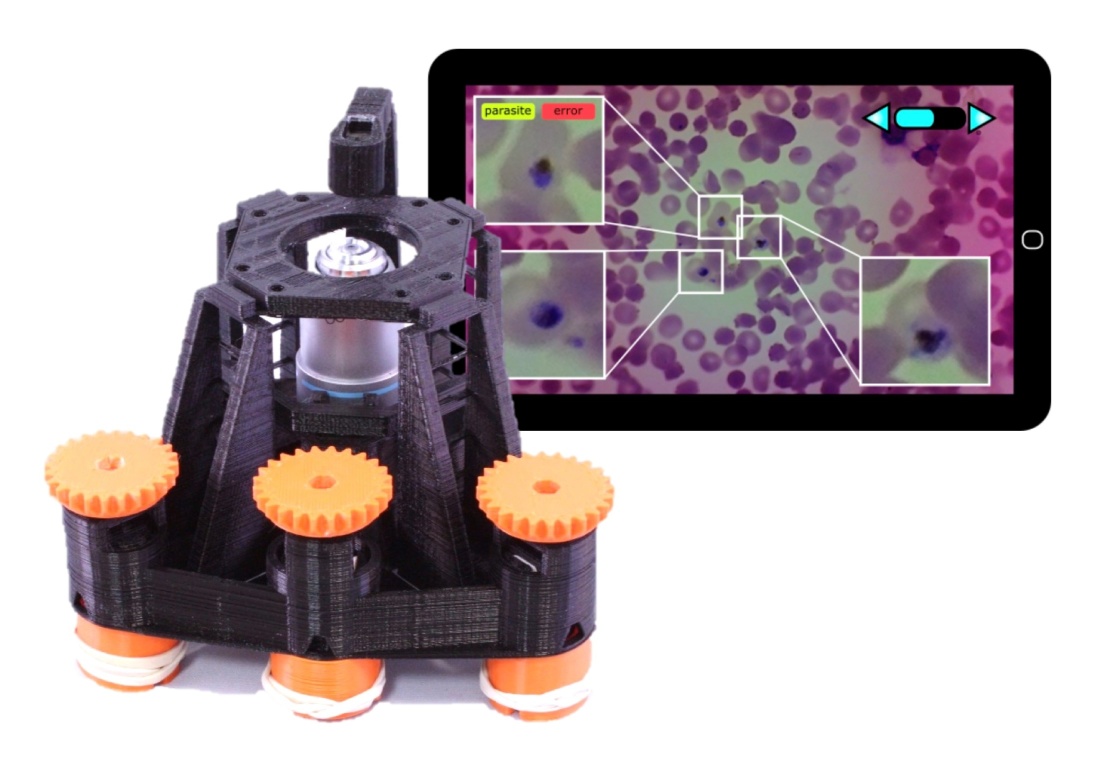

The best way to diagnose malaria remains microscopic examination of blood smears, to identify the plasmodium parasites that are responsible. This takes around 30 minutes of microscopy, done by a trained technician – skilled workers who are in short supply. The project will create an intelligent microscope that can greatly multiply the skills of a technician by scanning over the smears automatically, and allowing them to review only the suspicious blood cells on a tablet computer after the smear has been scanned.

The key to reliable, useful diagnosis with an automated microscope lies in computer vision; simply acquiring digital images and tiling them together into a digital smear is an important first step, but robust analysis of the digital images means the technician need not sift through many images of healthy cells. Instead, they can concentrate their efforts on parts of the image where the algorithm identified suspicious features. Once trained, the algorithm will be able to identify many parasites, only asking for the technician’s opinion in challenging, ambiguous cases when it could not identify objects with certainty. Fully automated counts of healthy and infected cells will then allow consistent quantification of test results, informing the clinician prescribing treatment and aiding in disease monitoring.

Computer vision is a powerful technique, but it requires high-resolution digital representations of blood smears in order to work. The project therefore has a hardware component, to create a slide-scanning instrument, capable of digitising blood smears in the field. This instrument will use low cost components and desktop digital manufacturing, so that it can be produced locally – freeing clinics from expensive international supply chains, and creating opportunities for local entrepreneurs that build valuable engineering and design skills. This approach has already been trialled with the first version of the microscope, which will shortly be available for purchase in Tanzania and Kenya, and it is hoped to achieve an even greater impact with a fully automated instrument.